- Home

- >Wool Preparation

Shearers Listing

Wool Collection Depots

The co-

operative grades

and markets close to 3

million pounds of raw

wool each

year; the majority of

this coming

from

Each of the three

general classes of

wool (fine,

medium and coarse) are

sold wherever

the best prices are

available.

Online Store

Wool Preparation Guide

Improved Quality

=

Increased Returns

The more care you take with your sheep, the better value you will get for your wool clip.

The type of feed, bedding, medicine etc all have an impact on your final wool payment. This starts long before you even think of shearing the sheep.

A Guide for the Care & Handling of your Wool Clip is full of useful tips and how to's that every wool producer should read.

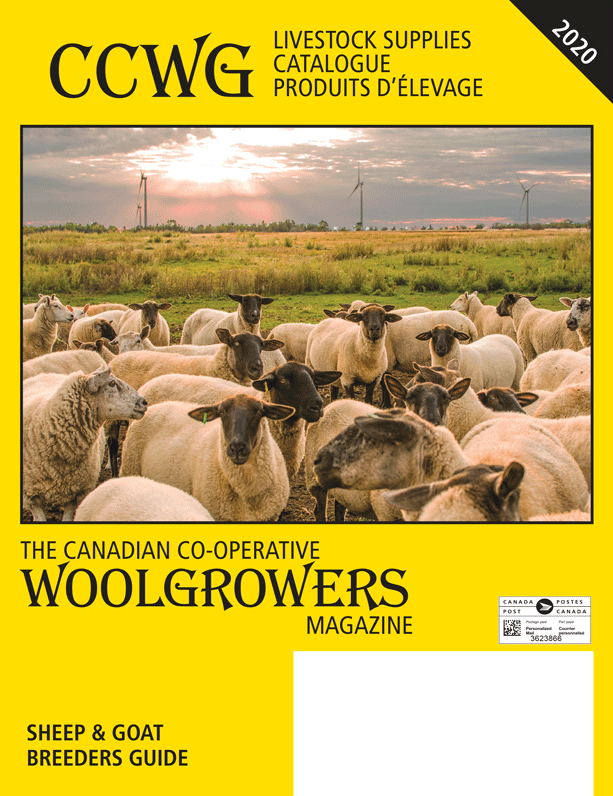

Download your copy today for better $$ return on your wool clip. Printed copies also available upon request. | The Co-operative publishes an annual magazine / catalogue which is designed to assist the wool producer with information and a mail order catalogue for sheep & livestock supplies.

Contact Us to receive your free copy today. |

|  |

Just a few of our videos available on our YouTube Channel

- Maximizing your wool clip with Brian Greaves

- Sheep Dog show

- Sheep shearing

- Weaving demonstration

- Moocall Calving Sensor on CTV National TV

Also available:

Wool Handling video CD and Preventing Wool Contamination video CD.

If interested, please send email with name and address (shipping & handling charges may apply).

Other Shearing videos:

Wool Links

- National Farm Animal Care Council website - Sheep Code of Practice pdf

Wool Production in Canada

Wool production in Canada (1.27MB)

Shareholder Wool Shipper Loyalty Reward Program (SWSLRP) SWSLRP-WPIR

The Board of Directors have approved a loyalty reward program proposed by management for CCWG shareholders that are also wool shippers. The purpose of this loyalty reward program is to recognize shareholder / wool shippers with a rebate on their wool clip.

Following each year-end and depending on the overall profit from all company business, the Board of Directors will allocate a percentage of the years profit to a reserve account for (SWSLRP). The rebate will then be paid to shareholder / wool shippers in the form of a CCWG profit sharing coupon which can be redeemed for purchasing products at any CCWG branch location. The profit sharing coupon will have an expiry date of 3 years from date of issue, will not have a cash surrender value and will not be transferable. This will be an added bonus for shareholder / wool shippers in addition to the standard shareholder benefits such as the dividend, discount plan etc. The calculation for the rebate will be based on the net weight of the current fiscal years wool clip at a pre-determined rate in cents per pound.

It has been at 7 cents per pound for the past several years.

This coupon must be presented at time of redemption.

Shareholder Application

Shareholder Application

Wool Preparation Incentive Rebate (WPIR)

1) Currently a bonus 2-8¢ per pound is paid on the total net weight of the wool clip (all grades including offsorts)

2) Eligibility is based on bright high yielding wool clips that have been well prepared and skirted with offsorts separated from main fleeces by a newspaper divider or packaged in a separate bag.

3) Shipped in well packed sacks.

Explanation: The objective of the wool preparation incentive is to reward producers with a bonus for those that have taken the time and effort to present a clean, well prepared and packaged wool clip for grading and marketing. At the time of wool grading, our wool grader assesses if the producers clip qualifies for the bonus, depending on the quality and presentation of the wool clip. Offsorts are defined as the bellies, stained wool and tags.

Code of Practice for Wool Preparation and Storage

To enable Canadian wool growers to achieve better wool preparation and higher financial returns the following are the recommended guidelines. Producers should also implement biosecurity measures to prevent and control the spread of disease. Please refer to The National Farm Animal Care Council Code of Practice for Sheep.

1) All sheep need to be emptied out before shearing. i.e. No feed or water to be administered to the sheep for a minimum of 12 hours prior to shearing. By carrying out this practice the sheep’s stomach and bladder will be empty and therefore the wool does not become contaminated with dung and urine. The sheep will also sit better for shearing as they do not struggle the same which enables the shearing process to be easier for both the shearer and the sheep. Never shear wet wool or pack wet wool.

2) The belly wool needs to be kept completely separate from the fleece wool. The shearer should remove and throw the belly aside as the sheep is being shorn, belly wool to be packed separately.

3) All short, stained wool and tags need to be removed from the crutch area as the sheep is being shorn. This wool is kept completely separate from all other types of wool and packed separately.

4) All fleeces should be thrown onto a wool table to enable the skirting of the fleeces to be performed in a proficient manner. Chaffy or bury wool should be skirted from the fleece and packed separately.

5) The board should be swept and kept clean between sheep as well as during the shearing of the sheep.

6) All fleeces should be shaken to remove any second cuts before rolling and pressing the fleeces.

7) When pressing the wool all the different categories of wool are to be pressed separately. There should be no mixing of the different wool types during shearing but when pressing at the end of shearing the different types of wool can be put into one bag but they need to be separated by sheets of newspaper.

8) All bags are to be sewn with butchers twine. Please do not use baling twine, wire, electric fence wire, or polyprop twine to sew the wool bags.

9) All bags need to be identified as to their contents.

10) Where possible during shearing the level of straw needs to be kept to a minimum and away from the shearing area to keep the contamination level to a minimum.

11) Coloured & Blackface sheep are to be separated and shorn last so as not to contaminate the white wool with coloured fibres.

12) Fleece preparation incentives of up to 8¢/lb is applicable for bright high yielding fleeces that have been properly skirted and packaged.

13) Maintaining a clean shearing board and floor is an important and continuous process. It must be done before, during and after shearing to insure a quality clip.

14) Wool should be packed in approved packaging and then stored in a dry environment in order to preserve optimum quality. Wet wool has no value and wool bags are not water proof.

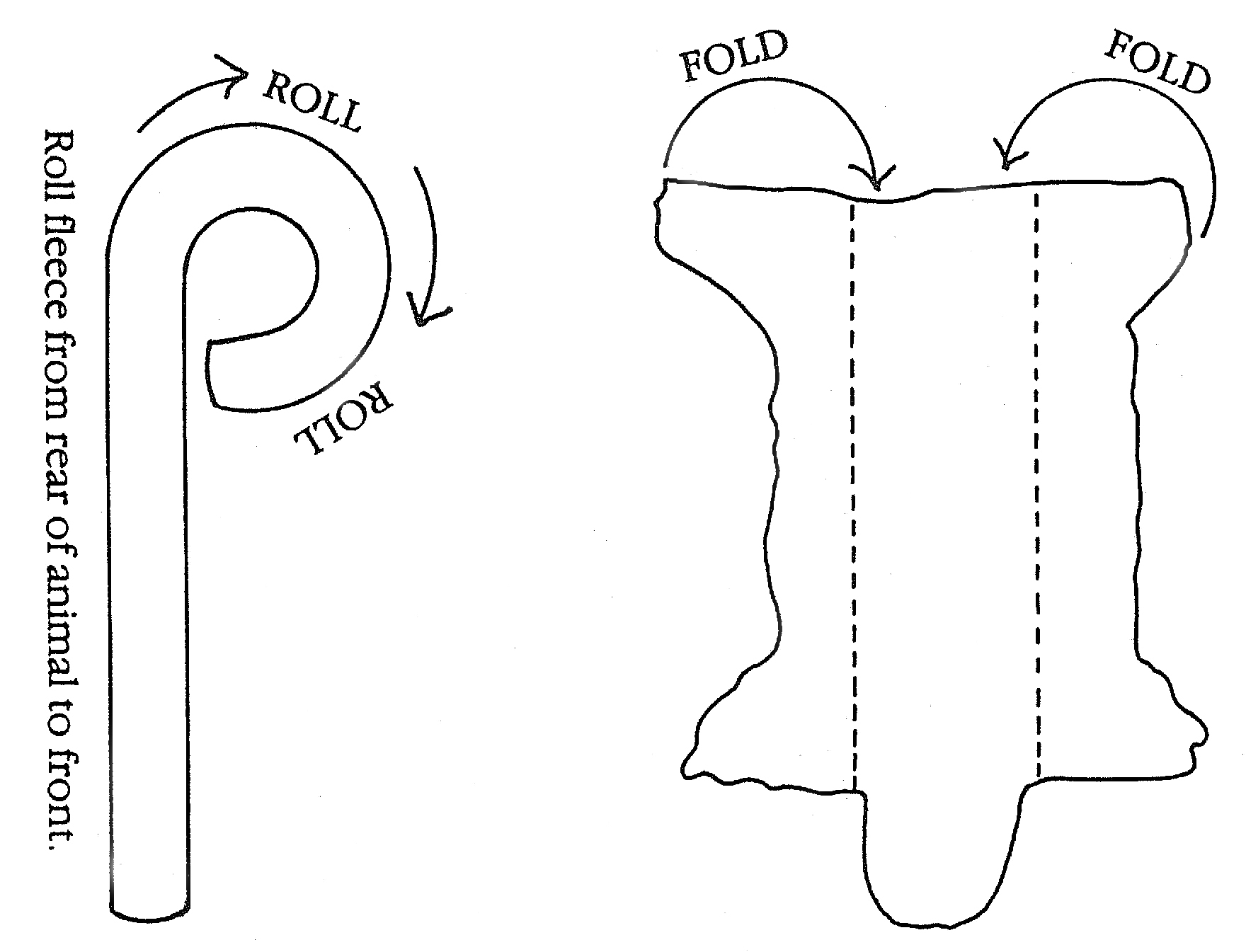

Rolling the fleece (all wools)

* Spread skirted fleece on skirting table or clean wool handling area, flesh side down

* Fold fleece into thirds

* Roll fleece from rear of animal to front

* Roll fleece flesh side out